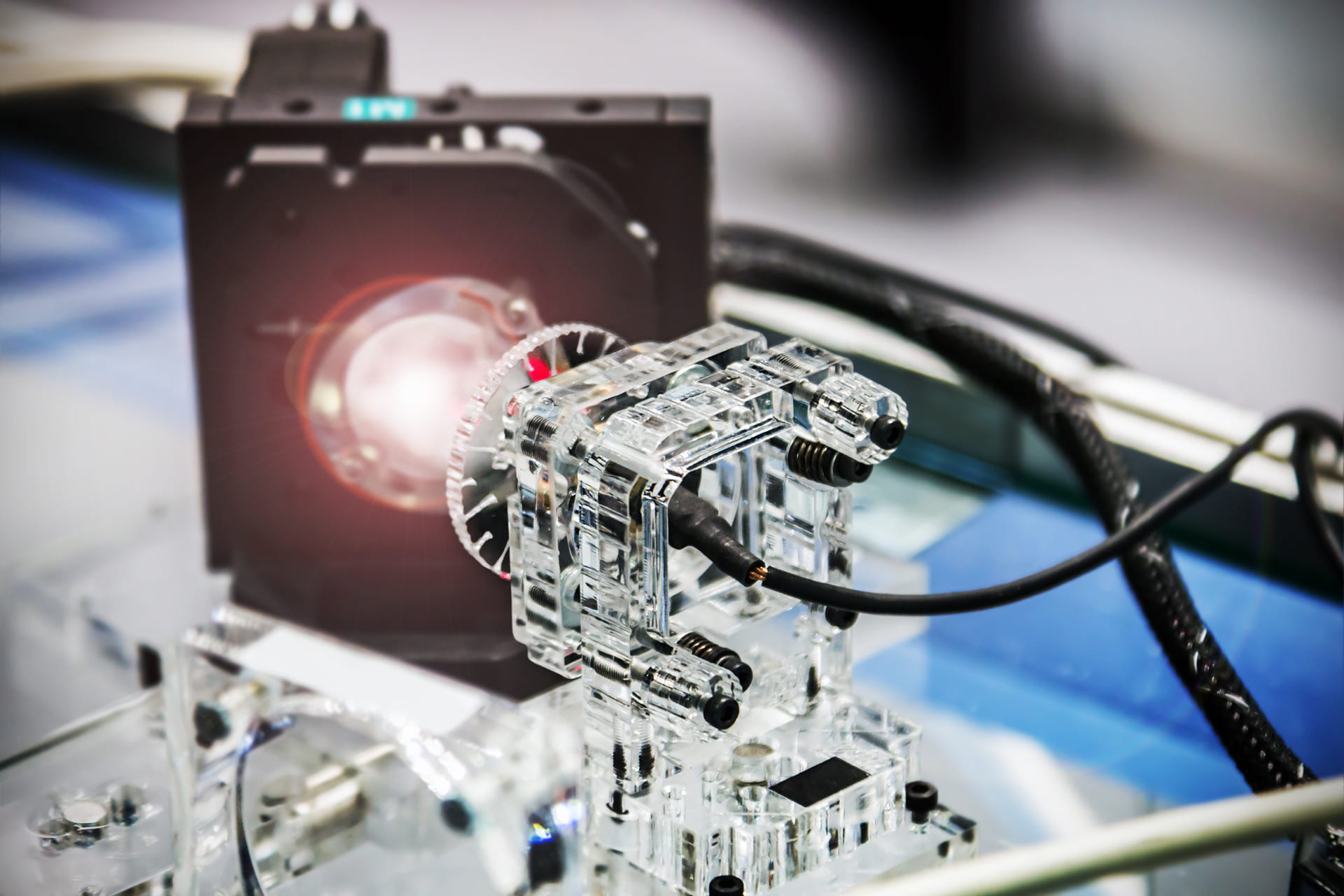

Pleksi is a type of plastic glass available in both colored and colorless varieties. It can be transparent, matte, colored, opaque, frosted, or dual-colored (black and white). It has an easily workable, cuttable, and drillable structure with a lightweight plastic composition. Typically, it is found in the market in flat sheets with a thickness of 1.5-2.5mm. It can be softened by heating at 90°C or in an oven at 90°C–115°C, allowing it to be molded into the desired shape. It is more durable and lighter than glass. Its only disadvantage is that, due to its thermodynamic nature, it is less resistant to burning. For reference, 90°C is approximately 194°F, and 115°C is approximately 239°F.